Contact

- Tel:180 381 66666

- Email : syg@kaiente.com

- Address:No. 191, Guanchang Road, Dalingshan Town, Dongguan City

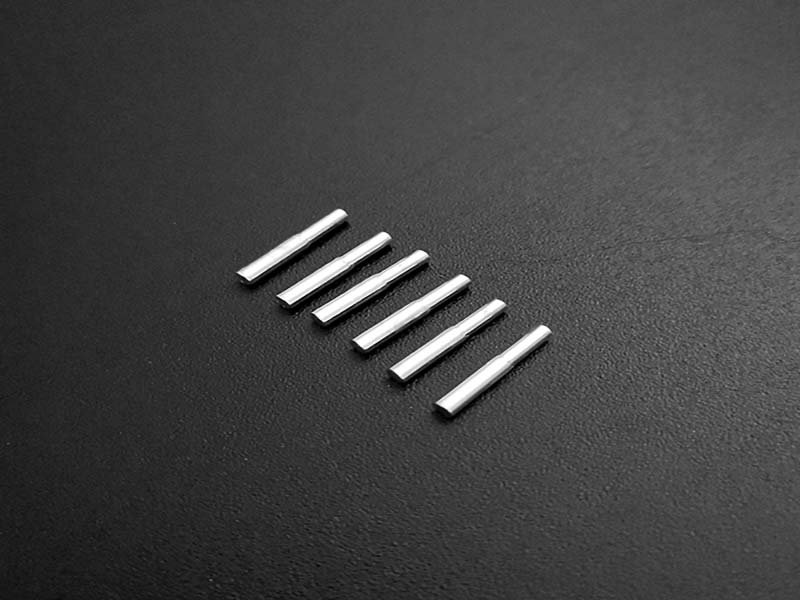

Metal stamping

- Metal stamping is a common metal processing method that applies force to a metal sheet to produce plastic deformation under the action of a mold, forming the desired shape and size

Metal stamping is a common metal processing method that applies force to a metal sheet to produce plastic deformation under the action of a mold, forming the desired shape and size. It is a commonly used process for mass production of metal components.

The basic steps of metal stamping include:

Design mold:Design and manufacture corresponding stamping molds according to the shape and size requirements of the product.

Material preparation:Select appropriate metal sheets as raw materials, cut and preprocess according to product requirements.

Clamping material:Place the metal sheet on the worktable of the stamping machine and secure it with a fixture.

Cutting:According to the design requirements of the product, perform drilling or cutting operations on the metal sheet.

Stamping forming:By the pressure of the stamping machine and the action of the mold, the metal sheet undergoes plastic deformation to form the desired shape.

Plastic surgery and repair:According to the needs, shape, correct, and trim the stamped parts to ensure their size and appearance quality.

Surface treatment:Surface treatment of stamped parts, such as painting, plating, polishing, etc., to improve their appearance and corrosion resistance.

Metal stamping has the following characteristics and advantages:

High efficiency:Metal stamping can quickly and continuously process metal parts, suitable for large-scale mass production.

High precision:Stamping molds have high precision and repeatability, and can manufacture parts with complex shapes and precise dimensions.

Good product quality:During the stamping process, the metal sheet is subjected to significant pressure, resulting in the reorganization and densification of the material's grains, which enhances the strength and hardness of the components.

Multiple process requirements can be achieved:Hardware stamping can meet various process requirements, such as cold stamping, hot stamping, bending, stretching, etc., with a wide range of applications.

Metal stamping is widely used in the manufacturing industry, involving various fields such as automobile manufacturing, home appliance manufacturing, aerospace, electronic products, etc. It is an important metal processing technology that is of great significance for achieving efficient production capacity and high-quality products