Contact

- Tel:180 381 66666

- Email : syg@kaiente.com

- Address:No. 191, Guanchang Road, Dalingshan Town, Dongguan City

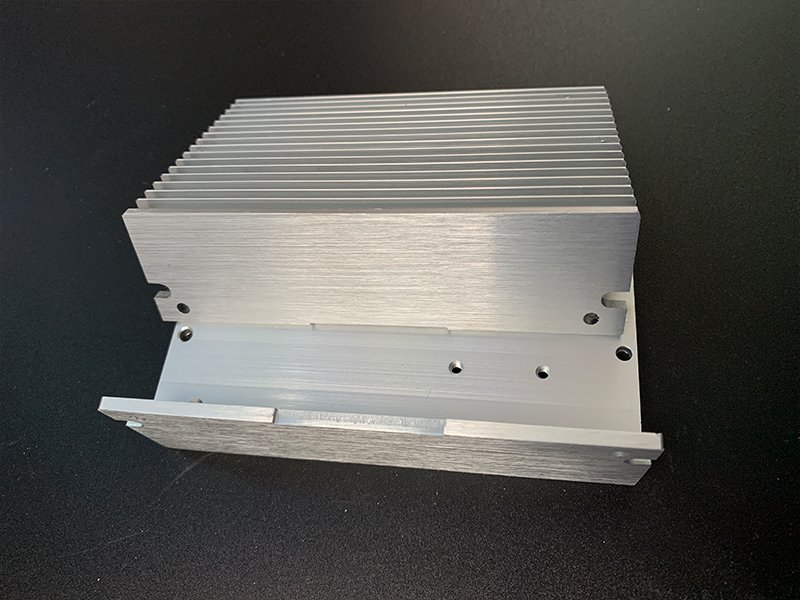

Heat sink

- Ltd. is a company specializing in the production of FR-4 epoxy boards, hardware stamping parts, electronic heat sinks (devices), aluminum alloy shells and other electronic materials manufacturers, such products are mainly used in switching power supplies, electronic transformers, intelligent controllers, household appliances and other electronic and electronic fields.

Nikai Technology (Dongguan) Co., Ltd. is a professional manufacturer of FR-4 epoxy board, metal stamping parts, electronic heat sink (radiator), aluminum alloy shell and other electronic materials, this kind of products are mainly used in switching power supply, electronic transformer, intelligent controller, household appliances and other electronic and electronic fields. The company has rich industry experience, professional design, manufacturing, inspection, business and other departments, self-set mold room, grinding machine, milling machine, lathe, wire cutting and other mold making equipment, can quickly complete sample preparation, mass production. The inspection department has projectors, environmental protection testers and other testing equipment, and can complete the inspection of strict products by itself. The company has passed ISO 9001:2015 quality system certification; IATF 16949:2016 Quality system certification. Since its establishment for many years, with excellent quality, perfect service, reasonable price, has been praised by many customers!

1. Introduction to FR-4 epoxy board products:This material is made by mixing electronic grade glass fiber cloth with epoxy resin and subjected to high temperature and high pressure. It has the characteristics of high voltage resistance, good insulation performance, and fire resistance (with a fire rating of 94V0). Mainly used in electronic transformers, inductors, power insulation and other products. Our company provides full process services for the entire product, including pressing, stamping, drilling, installation of PIN needles (fake feet), and other processing steps. The fastest sample can be produced in one hour, the mold can be produced in two days, and mass production can take three days, achieving a relatively fast level in the industry.

2. Metal stamping parts:The substrate consists of various metals such as copper, iron, aluminum, stainless steel, etc., with sheet metal being the main component; There are various processing methods such as single punch and continuous punch, combined with surface treatment technologies such as electroplated gold, silver, nickel, tin, zinc, powder coating, and baking paint, which can quickly complete various small and large batch order requirements.

3. Introduction to electronic heat sink:There are various types of substrates such as aluminum plates, aluminum profiles, copper materials, etc., mainly used in various high-power appliances such as switching power supplies, power adapters, stepper drives, and household appliances. The processing steps include sawing, stamping, drilling, tapping, milling, drawing, sandblasting, oxidation, and riveting.

4. Introduction to Aluminum Alloy Shell:The substrate includes aluminum plate stamping, aluminum profiles, and aluminum die-casting, and the surface treatment methods include oxidation and powder coating. It is mainly suitable for packaging various products such as transformers, inductors, inverters, etc. It has the characteristics of good heat dissipation, beautiful appearance, and excellent performance.